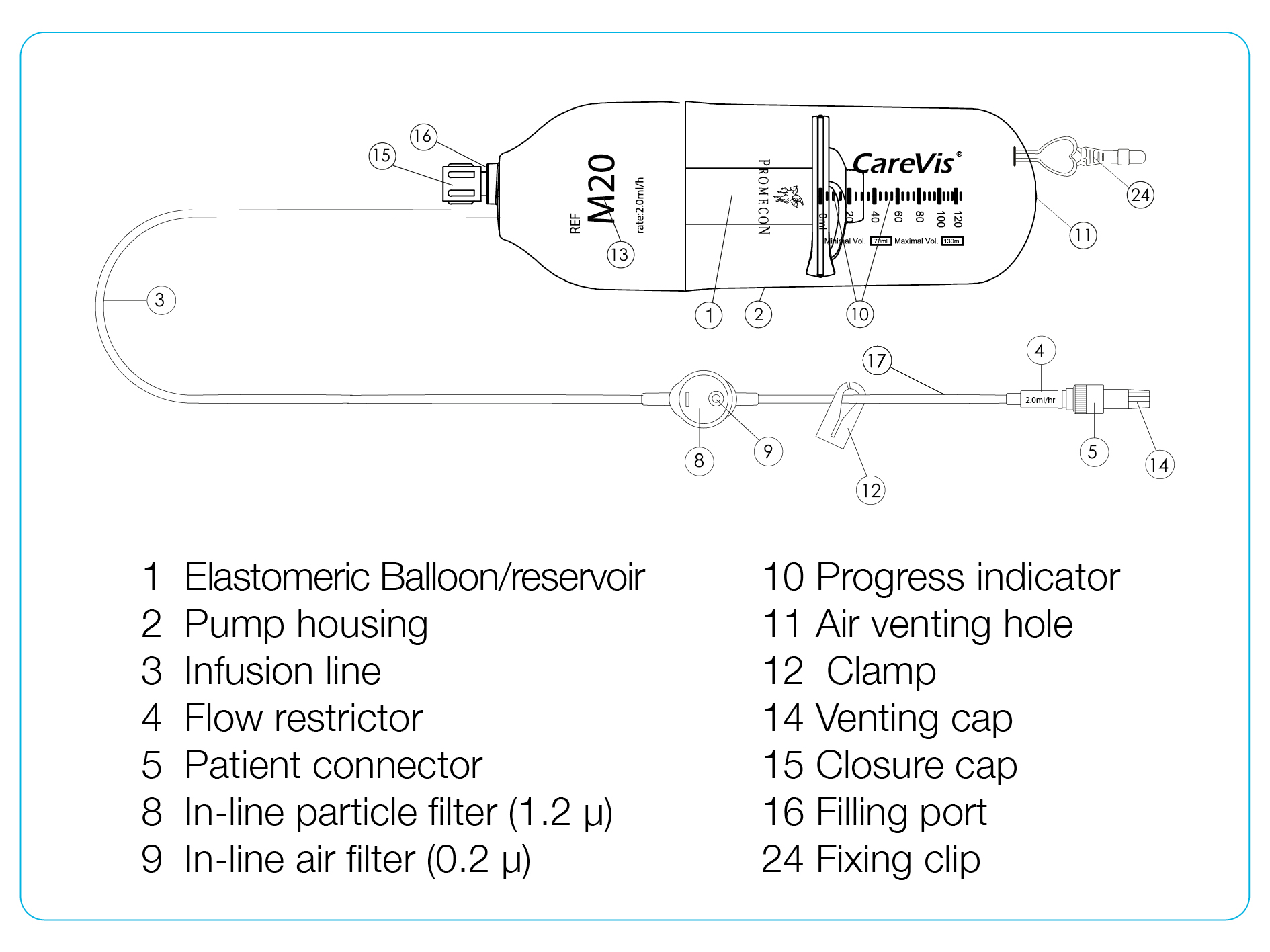

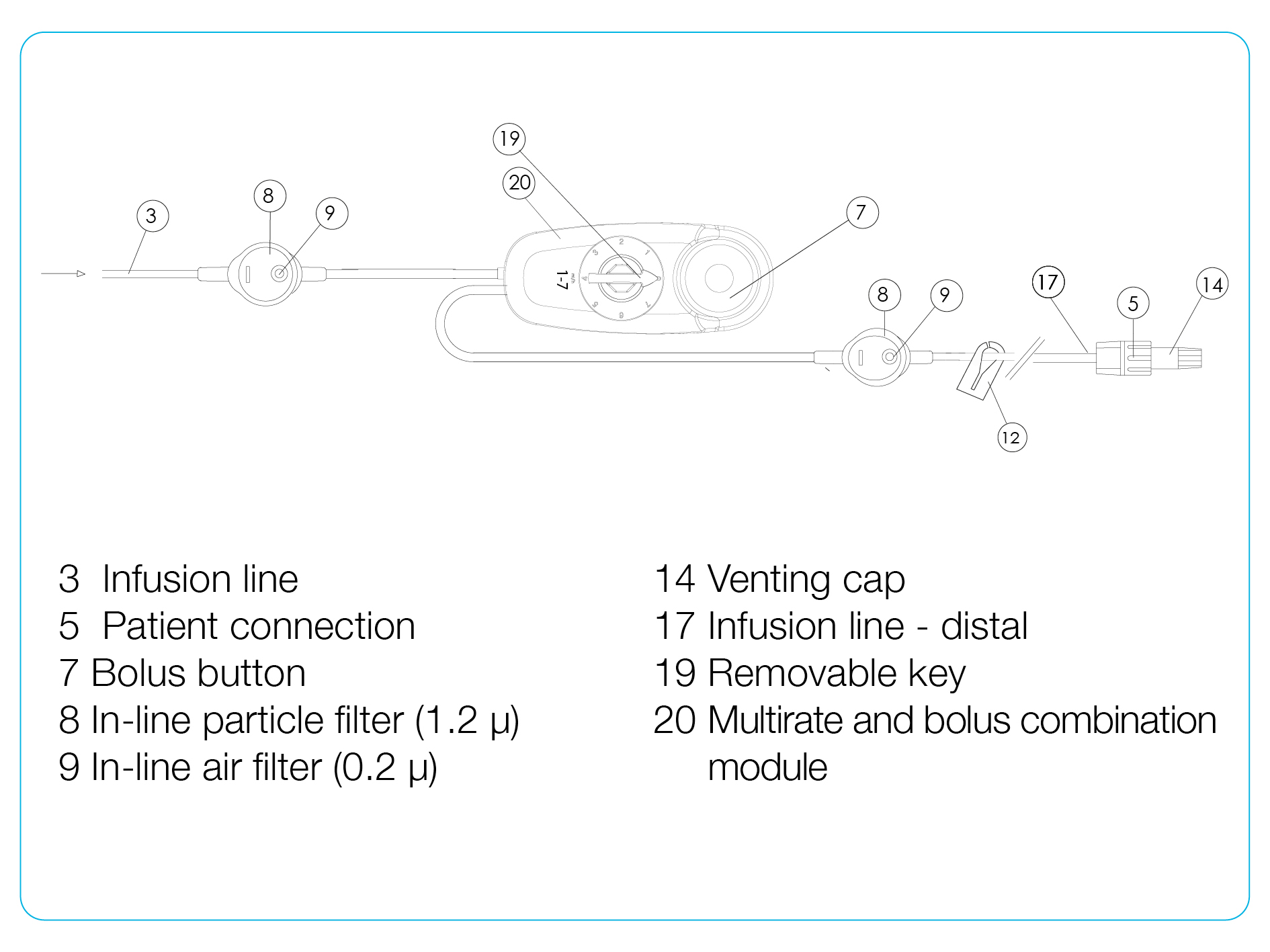

Elastomeric infusion pumps are designed for continuous drug delivery, on-demand delivery or a combination of continuous and on-demand drug delivery (patient-controlled analgesia, PCA).

Elastomeric pumps offer a safe alternative to electronic pump systems for various therapeutic areas and applications. They are intended for single use and, in contrast to electric infusion pumps, work without external energy sources such as batteries or electricity. But how is the drug delivery of elastomeric pumps controlled and a reliable flow rate ensured?

Drug delivery with elastomeric pumps

The pumping function is provided by the continuous contraction of an elastomeric balloon filled with drug. Inside the infusion line connected to the balloon is a flow restrictor, also called a capillary, which limits the flow rate of the elastomeric drug by the pressure difference between its inlet and outlet.

The predefined flow rate is controlled by one or more flow restrictors that are installed in the infusion line. The flow restrictor ensures the correct dosage of the infusion solution. The flow rate decreases when the flow restrictor is longer or the radius of the flow restrictor is smaller. Conversely, the flow rate increases with a shorter or wider flow restrictor. The principle of operation of the elastomeric infusion pump is based on the physical law of Hagen-Poiseuille.

- Cross-sectional area of the flow restrictor (equivalent to the diameter for pipe cross-sections)

- Length of the flow restrictor

- Temperature (at the flow restrictor and the pump itself)

- Viscosity of the medication (temperature-dependent)

- Pressure difference between balloon reservoir and patient connection

The pressure difference is influenced by the volume of the elastomeric balloon and, to a lesser extent, by the height difference between the pump case and the distal connection (please note the maximum filling volumes in the instructions for use). Holding the pump body above the distal port increases the pressure gradient and thus the current flow. Holding the pump below the port has the opposite effect, so it is important to ensure that the pump is at the same level during application.

Temperature changes also have a proportional effect on the flow rate. It rises or falls by about 2% for every 1°C (1.8°F) increase or decrease in temperature. Therefore, the pumps should be protected from sunlight or cool temperatures and should be stored at room temperature. Generally, the flow restrictors of strictly continuous pumps with pre-set flow rate are calibrated to skin temperature to counteract temperature fluctuations. In such models, the flow restrictor must be fixed to the skin with a plaster. The progress of the infusion is indicated by the progress indicator on the protective housing. The infusion is finished when the pump balloon lies flat on the central piston and is no longer bulging and is no longer curved.